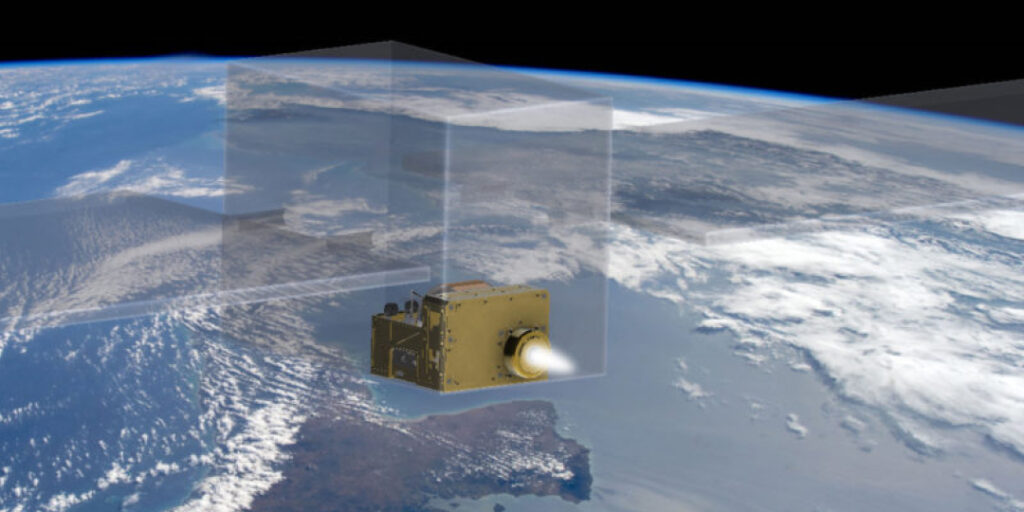

Phase Four builds Maxwell, a propellant agnostic satellite thruster. Traditional propellants like xenon and krypton can be rare, expensive, and have long sourcing lead times. Maxwell can be powered by a myriad of fuel sources including water, nitrogen, and iodine, as well as traditional propellants like xenon and krypton, lowering development costs and shortening lead times which might otherwise delay launch.

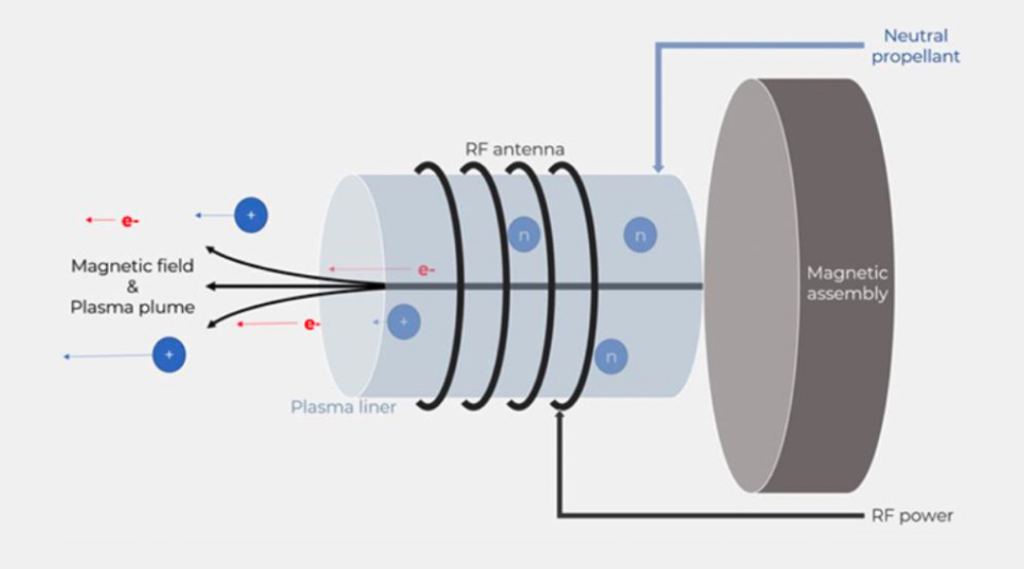

Maxwell creates thrust by using an RF electromagnetic field to convert propellant into an ionized plasma. The RF-excited plasma thruster design replaces the high voltage cathodes used in more traditional plasma generators with an antenna, reducing manufacturing costs and weight for the overall system. A permanent magnet array surrounding the antenna generates a magnetic field that directs the hot plasma out of the thruster, creating forward movement for the satellite.

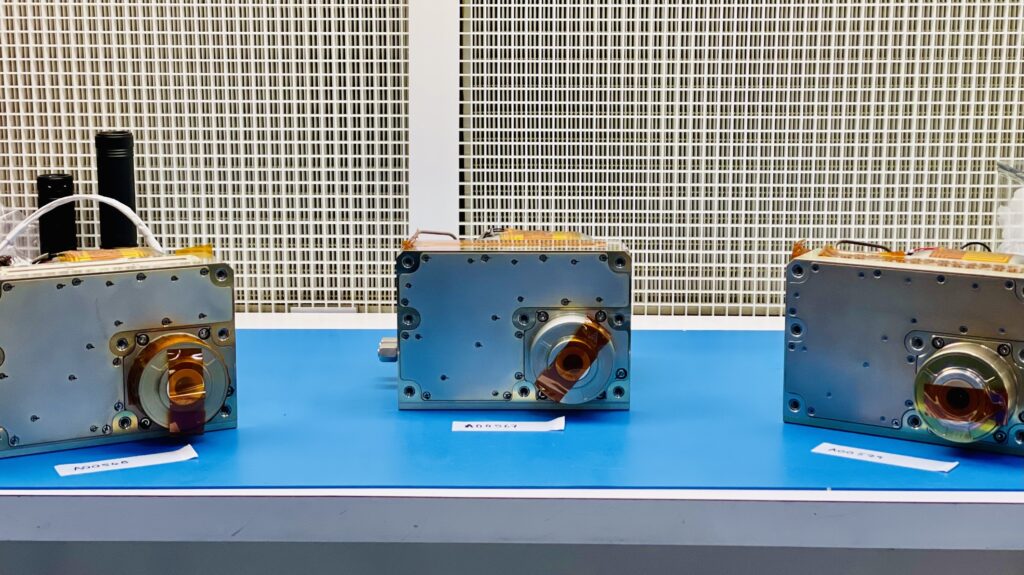

Second Order Effects (SOE) helped Phase Four architect, design, develop, and test two critical components in their first product, Maxwell Block 1. Phase Four came to SOE with the architecture for the Propellant Controller and needed help developing a few key features including safety monitoring for the board, reading the temperature of the propellant tank, and reviewing the board’s heat sinking. During SOE’s review of the system architecture, SOE and Phase Four also conceptualized the “Thruster Controller”: a highly efficient resonant mode DC-DC Converter which steps up the bus voltage, in turn biasing the RF amplifier used to excite electrons in the gas.

True to its name, the Propellant Controller provides a means of controlling and monitoring propellant flow from Maxwell’s tanks to its thruster chamber. Embedded code running on a microcontroller in the Propellant Controller drives solenoid controlled valves to direct and control the flow of propellant into the thruster chamber, and measures and transmits telemetry back to the spacecraft data bus. The design accounted for radiation induced single event effects faults, and mitigated potential upsets using watchdog timers, redundancy, and other techniques.

A key component of the Thruster Controller was the custom, low parasitic transformer that SOE designed, built, and tested in-house. The Thruster Controller also monitors critical safety features and shuts the system down if it reaches an unsafe operating temperature or exceeds a safe voltage/current.