Astrolab is building a multifunctional planetary rover. The FLEX Rover (Flexible Logistics and Exploration Rover) provides human transport, last-mile cargo delivery, construction, sample collection, and other mission critical activities for exploring the Moon and Mars. FLEX has a scoop to collect extraterrestrial samples, retractable solar panels to generate power, a modular robotic arm to aid in construction, and an active suspension system to lift itself over obstacles.

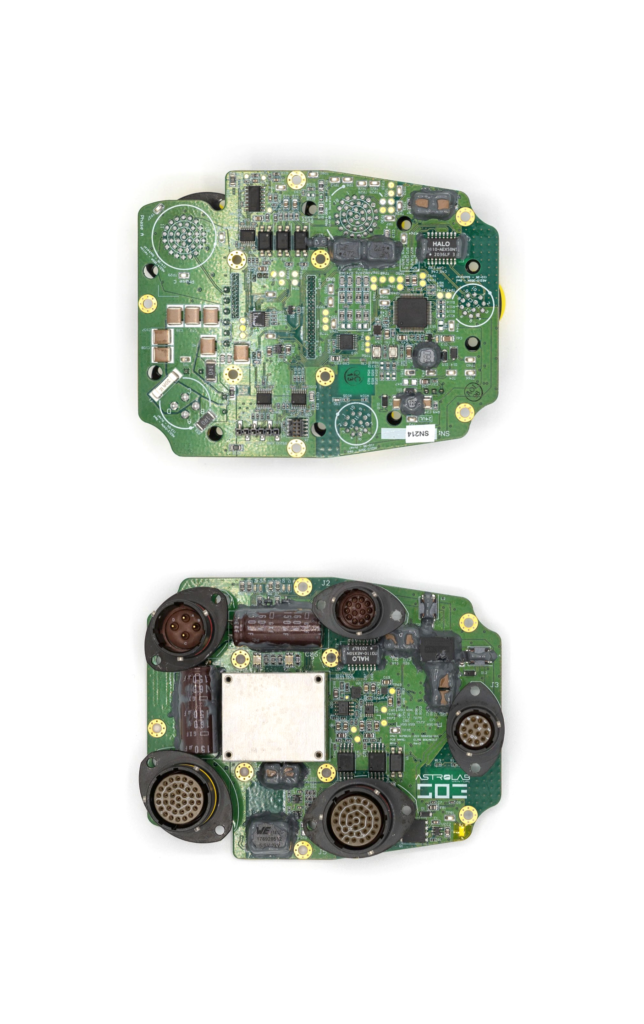

Second Order Effects (SOE) designed, tested and fabricated a set of Brushless Direct Current (BLDC) motor control boards used for Astrolab’s FLEX terrestrial prototype with a mix of custom and commercial off-the-shelf (COTS) components. These motor control boards are multifunctional and control the rover’s robotic arm as well as its four independently-steered wheels. In addition to the motor control boards, SOE designed a bathtub-style enclosure to house the PCBAs and protect them from dust and debris while still allowing adequate cooling for the motor driver. Although these motor control boards are designed for testing in a terrestrial setting, future iterations will need to be rad-hard to withstand higher radiation levels in space. To learn more about Astrolab’s FLEX rover, be sure to check out Astronaut Chris Hadfield’s test drive in the Mojave Desert.