Our client, a satellite provider, built a large satellite to house a terrestrial-looking telescope. The satellite included an extremely sensitive optical system which needed to be thermally monitored and controlled to prevent damage to the optics, which were critical for the mission success. Second Order Effects (SOE) was hired to design, develop, build, qualify, and produce a programmable temperature controller

Our challenge was to deliver a reliable, configurable thermal controller that would be qualified for a long-term Geosynchronous Transfer Orbit (GTO) mission while minimizing development effort and overhead while optimizing for tight timelines and efficiency.

Our client needed heaters to ensure that their sensitive optical equipment did not fall outside of operating temperature parameters for the large temperature swings that occur in space. These heaters and their temperature sensors would be mounted in thermally sensitive areas of the optics.

The client wanted a controller that would precisely turn on heaters when thermal environments dropped to a level that could damage the telescope. Since the thermal environment would be difficult to characterize until the majority of the satellite was built and tested, the controller’s temperature response needed to be configurable late into the program

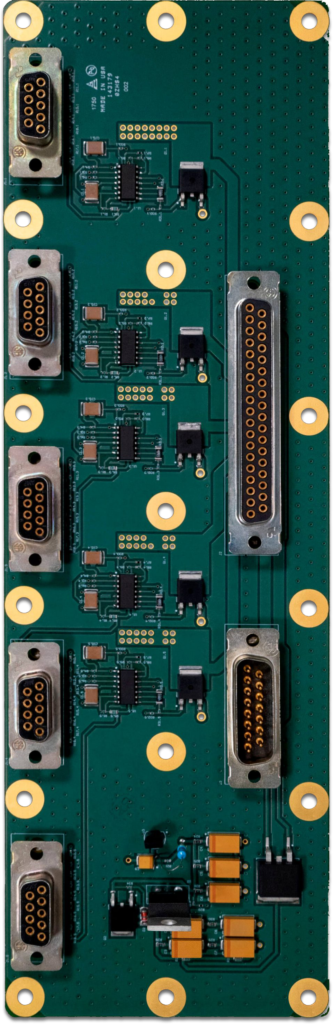

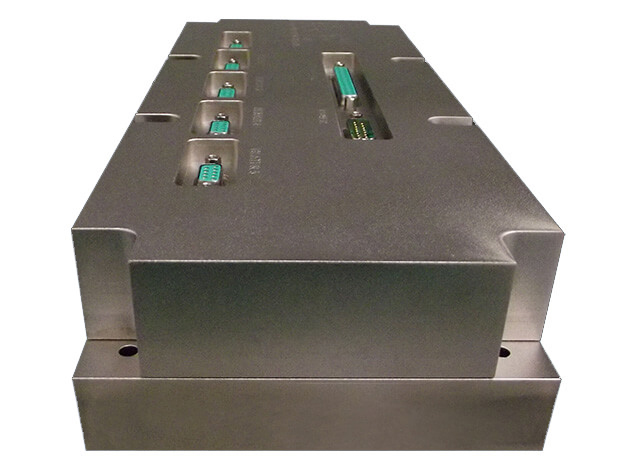

We developed a 5-channel, closed-loop, stateless and easy-to-use temperature controller called the Space Heater Hardware Adjustable Controller (SHHAC) using radiation-hardened parts. It uses physical wiring on an external connector to program the controller and avoid the lengthy process of aerospace qualified software — a simpler solution. We managed and supported the production of the avionics box from design through integration into the flight vehicle, ultimately ensuring a highly reliable solution for our client.

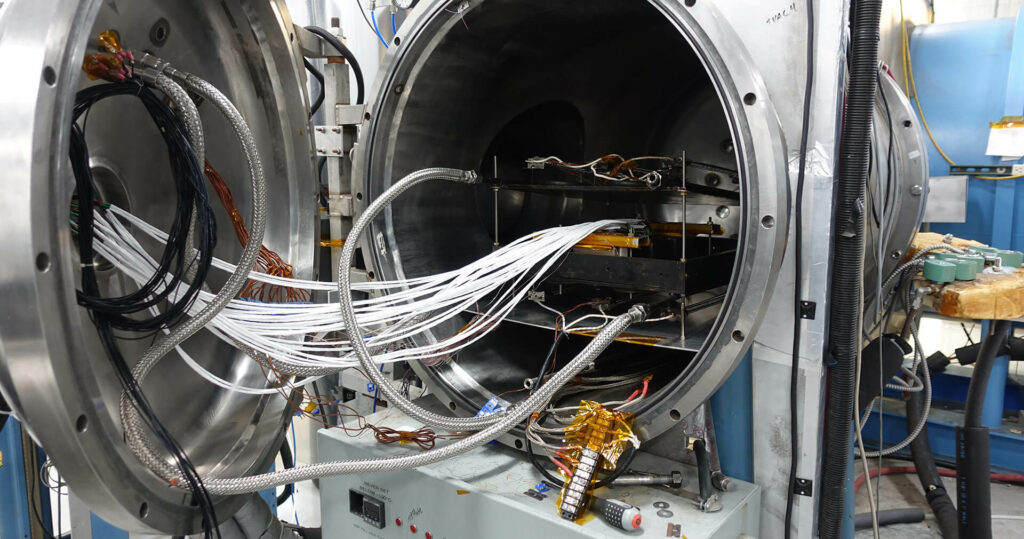

SHHAC underwent a series of tests prior to production, passing hardware qualification and acceptance test cycle in accordance with SMC-S-016. We tested for unit qualification:

The temperature controller is mounted on a satellite and is currently in orbit.